The paperboard manufacturing process starts with the receipt of bales of recycled cardboard and paperat the pulp & paper plant. The bales are immersed in an agitation tank of 165° F water, breaking the paper down into fibers. The de-fibered paper or paper pulp is processed, separated by color, and temporarily stored in an under-floor “chest” (storage tank) where it circulates until needed. Pulp from the chest is pumped in a 4% solution to a paper machine that evenly distributes the pulp onto a fabric belt. Additional layers are added until the paper reaches the desired thickness, then it is run through a series of heated drying rolls. Starching, cutting, and rolling finish the paperboard process.

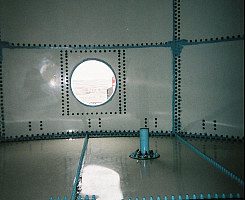

Specifics of the tank shows a hatchway to the “chest”. The hatchway will usually measure 24 inches square and is raised approximately 22 inches off the ground, with the chest underneath about twelve feet deep. A heavy metal grate is fitted to the hatchway. Paper pulp is pumped into the chest through a four-inch diameter pipe passing down through the hatchway. Inside the tile-lined chest is a propeller agitator that circulates the pulp.

U.S. Department of Labor, OSHA Federal OSHA will provide information on safety and health standards of Pulp & Paper Plant and Tank Operation, on request.

- Services

- Liquid Tank Projects

- Dry Tank Projects

- Facilities

- Locations

- Locations

- Territory Maps

- Locations

- Services

- Services

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Services

- Services

- Services

- Products

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Applications

- Products

- Facilities

- Products

- Products

- Products

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Liquid Tank Projects

- Dry Tank Projects

- Liquid Tank Projects

- Testimonials

- Dealers