Globaltherm can provide an extensive line of tank insulation products and services

Globaltherm provides design and manufacturing of both vertical standing seam and horizontal prefabricated tank and vessel insulation systems for both heated and cold storage applications. Each system is manufactured to meet or exceed the specific operating conditions providing maximum insulation value.

Our insulation system designs incorporates many choices of insulation materials including composites and inclusive of several jacketing options, such as aluminum, galvalume and stainless steel; all are offered in various thicknesses, finishes, and colors. Our capabilities include insulation systems for all types of storage tanks, spheres, vessels, drums, emissions hot air ductwork, digesters, precipitators, reactors, and other specialty applications.

Globaltherm’s insulation systems are used at liquid storage terminals, refineries, petrochemical facilities, utilities and wastewater plants, power generation facilities, fire protection applications, and for food & beverage storage.

Benefits of Globaltherm Insulation Systems

Our manufacturing design speeds the installation process and reduces costs.

Using only the highest quality materials and construction standards results in exceptional products capable of withstanding most any weather challenge.

We offer every aspect of the total turnkey solution—engineering, project management and installation.

We understand the importance of making these tanks pleasing to look at so they fit into the landscape around them. We use only metal-sheathed systems, offered in a variety of standard colors. On many projects we have worked closely with design architects to help create the look they require.

Fast and Effortless Installation by Professional Crews

We install tank insulation systems with field crews who are factory-trained, direct employees. Our construction crews receive more than 120 hours of in-house safety training. This guarantees your project is completed safely and efficiently. Globaltherm has earned an impressive safety record—our EMR reflects a safety record substantially better than the industry average.

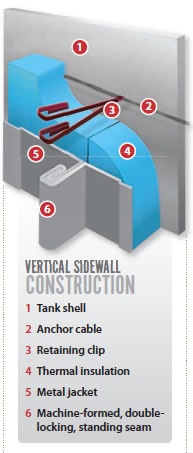

Vertical Sidewall System

Globaltherm manufactures a vertical sidewall system that consists of foil-faced polyisocyanurate foam insulation, in various thicknesses, laminated to a stucco-embossed, polyester-paint-finish, aluminum outer sheathing. Each standing seam is 24” wide, with lengths up to 53 feet. Our design allows us to accommodate any tank height. The insulation panels are secured to the tank by an internal cable-and-clip system that is secured within the standing seam of each panel.

Horizontal Sidewall System

Globaltherm manufactures a horizontal panel system that consists of foil-faced polyisocyanurate foam insulation in various thicknesses, laminated to a metal outer sheathing. Each panel is factory-curved to match the tank's radius. Panels are secured to the tank with 3"-wide aluminum or stainless steel external banding spaced on two-foot vertical centers. Unique tensioned “bandsion assemblies” are installed at calculated intervals in each band row. This allows for operational expansion and contraction of the insulation for climate fluctuations, such as extreme temperature changes. Additionally, individual horizontal panels are removable so that access can be gained to the tank sidewall for inspection or repair.

Standing-Seam Roof Designs

Globaltherm's standing-seam metal roof insulation system is available as a radial design and may be installed on any shape roof over many suitable insulation materials, including:

- Mineral Wool

- Fiberglass

- Polyisocyanurate Foam

- Calcium Silicate

- Expanded Perlite

- Aerogels

- Foamglas ™

This system can be installed with either welded or non-welded roof plate attachments, allowing the flexibility of in-service installation.

Flat-Panel Roof Designs

Globaltherm's flat panels include gore and trapezoidal designs.

The different panel designs allow our systems to be installed on virtually any type of surface shape required and can be applied over many insulation materials, including:

- Mineral Wool

- Fiberglass

- Polyisocyanurate Foam

- Calcium Silicate

- Expanded Perlite

- Aerogels

- Foamglas ™

Various methods can be utilized to accommodate installations on any tank type. Attachment methods can be internal/external, depending on application requirements.

Globaltherm’s tank insulation services are not limited to but include the following:

- Anhydrous Ammonia

- Asphalt

- Beverages

- BioDiesel

- Brewery

- Butane/Propane

- Chemicals

- Ethanol

- Wastewater Treatment

- Petrochemicals

- Chilled Water T.E.S. Systems

- Fire Protection

(We can design an insulation system that meets the National Fire Protection Association (NFPA) 22 standards.) - LPG

- Spheres