About Duratech Systems

Located in Redford, Michigan, Duratech Systems became part of the TF Warren Group in June 2021. This acquisition was a significant milestone for the group, enabling us to offer rubber lining services within the United States. Prior to this, all rubber projects were handled in Canada by Brant Corrosion Control, another TF Warren company.

For over four decades, Duratech Systems has been a leading rubber applicator in the U.S. Founded as a father-and-son business, we have grown substantially through our unwavering commitment to customer satisfaction and exceptional quality.

Our Solutions

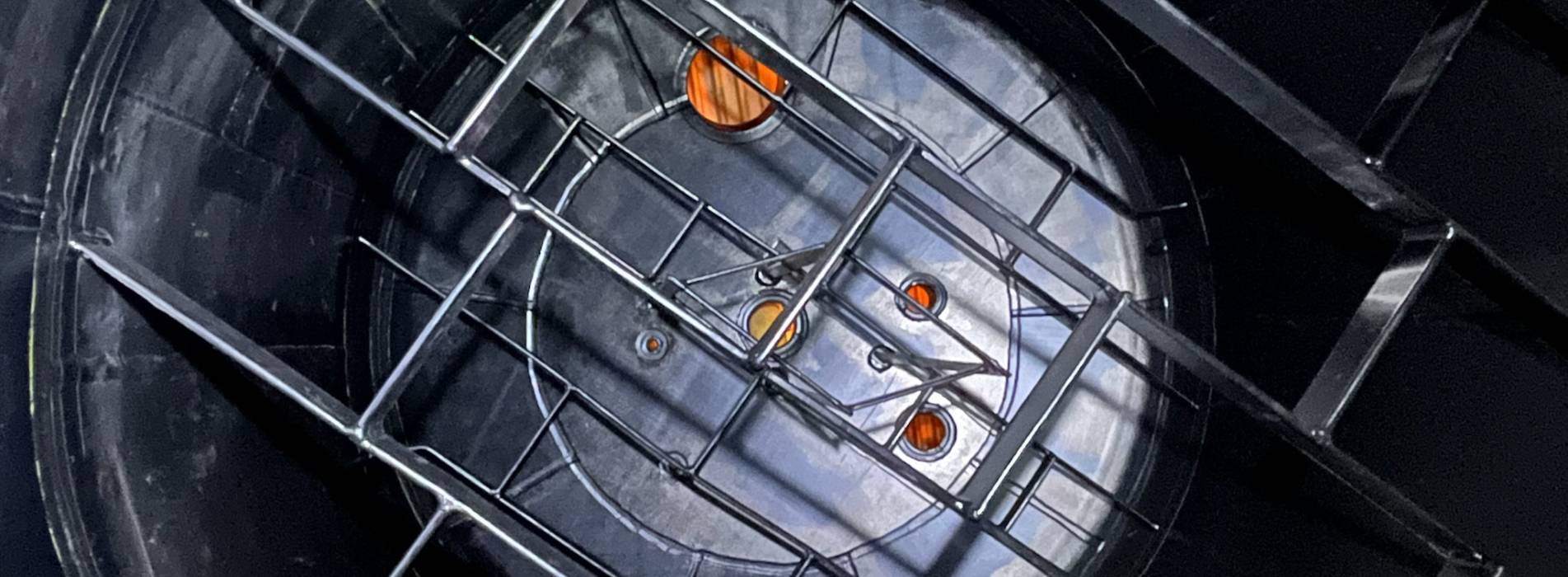

Our team of professional applicators is skilled in lining pipe interiors, mixers, intricate components, and large API650 storage tanks. We perform these services both in our shop and on-site. Specializing in turn-key projects, we manage rubber removal, abrasive blasting, and relining, all managed to meet our customers’ schedules.

We have expanded our capabilities with a new roll shop, specializing in rubber and urethane roll coverings for steel processing facilities across the United States.

Why employ Duratech Systems?

- On-site rubber lining inspections and repairs

- Long history of successful projects

- Dedication to high quality

- Expert management and applicators

- Competitive pricing

- Contract maintenance service agreements

Industries Served

- Water & Wastewater

- Metals & Minerals

- Industrial Manufacturing

- Chemical Processing

- Food & Beverage

- Power Generation

- Steel Processing

What we do

Rubber Linings Shop & Field

Different applications require unique elastomers and Duratech Systems specialize in installing all of them. We work with our customers to meticulously evaluate the temperature, chemical composition and concentration of the conveyed materials to determine the optimal compound for their specific application.

- Natural Rubber Compounds:

- Soft natural rubber – good for abrasive environments and general-purpose chemical resistance

- Semi-hard – used in water treatment equipment and oxidizing/plating solutions. FDA compliant options are available

- Ebonite (bone-hard) – suitable for valves and piping systems

- Synthetic Rubber Compounds:

- Neoprene – excellent UV and ozone resistance for general purpose abrasion and chemical resistance.

- Chlorobutyl – good chemical resistance for most acids and caustics. FDA compliant options are available.

- Bromobutyl – superior temperature resistant to acids and caustic solutions up to 260°F

- Nitrile – use for oil tank linings or when hydrocarbons are present.

We excel in lining pressure vessels, over-the-road tankers, mixing equipment, and any storage or processing equipment requiring corrosion and abrasion protection.

Our rubber lining services are available both at our facility and in the field, ensuring the highest quality in the industry. We uphold the highest standards and are dedicated to protecting your most valuable assets.

For a detailed explanation of our on-site capabilities tailored for your project, please contact our office today.

Duratech Systems is an approved applicator for all major sheet rubber compounders, including:

- Polycorp (formerly B.F. Goodrich)

- Blair Rubber (formerly Goodyear)

- Rema Tip-Top

- Steuler – KCH

Industrial Roll Covers

We specialize in providing rubber formulations tailored for the steel and aluminum processing industries. Our commitment to exceptional customer service includes dedicated trucks for picking up your rolls and delivering them back once completed.

Duratech Systems Equipment:

- 12’ Dia. x 50’ Long Autoclave

- 54” Dia. x 54” Long Autoclave

- 15’ x 55’ and 24’ x 40’ Gritblast Rooms

- Portable Sandblasters

- Truck Fleet

- Cold Storage for Rubber

- 10-ton Overhead Crane

- 2-ton Overhead Crane

- Poreba manual lathe, swing over bed 32”, between centers 312”, Remco SH 1200 series medium speed profile grinder attachment

- Bertram manual lathe, swing over bed 26”, between centers 192”

- Remco Universal strip builder USB 250