Projects

Equipment

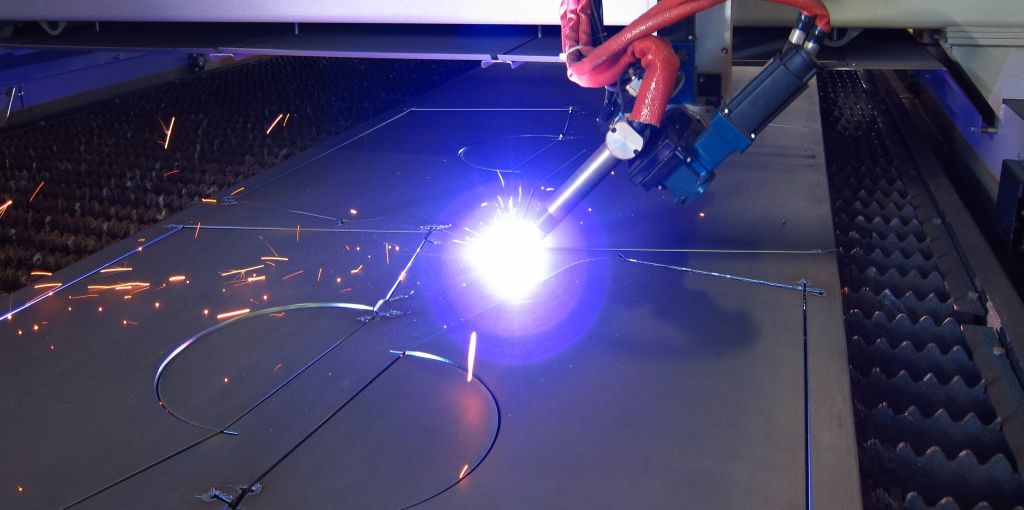

Automated Blast Equipment

- Clean blast with no dust or contaminants left on substrate

- Eliminates the need for containment

- Less hazardous for surface preparation crews and surrounding community

Industrial Vacuums

- Fast clean up

Dehumidification Units

- A fleet of DH equipment from 2250 CFM to 10,000 CFM readily available

- Units maintained to meet or exceed dehumidification specifications to provide high quality surface preparation for a better end product

Generator Units

- A fleet of generator units from 5KVA to 180KVA readily available

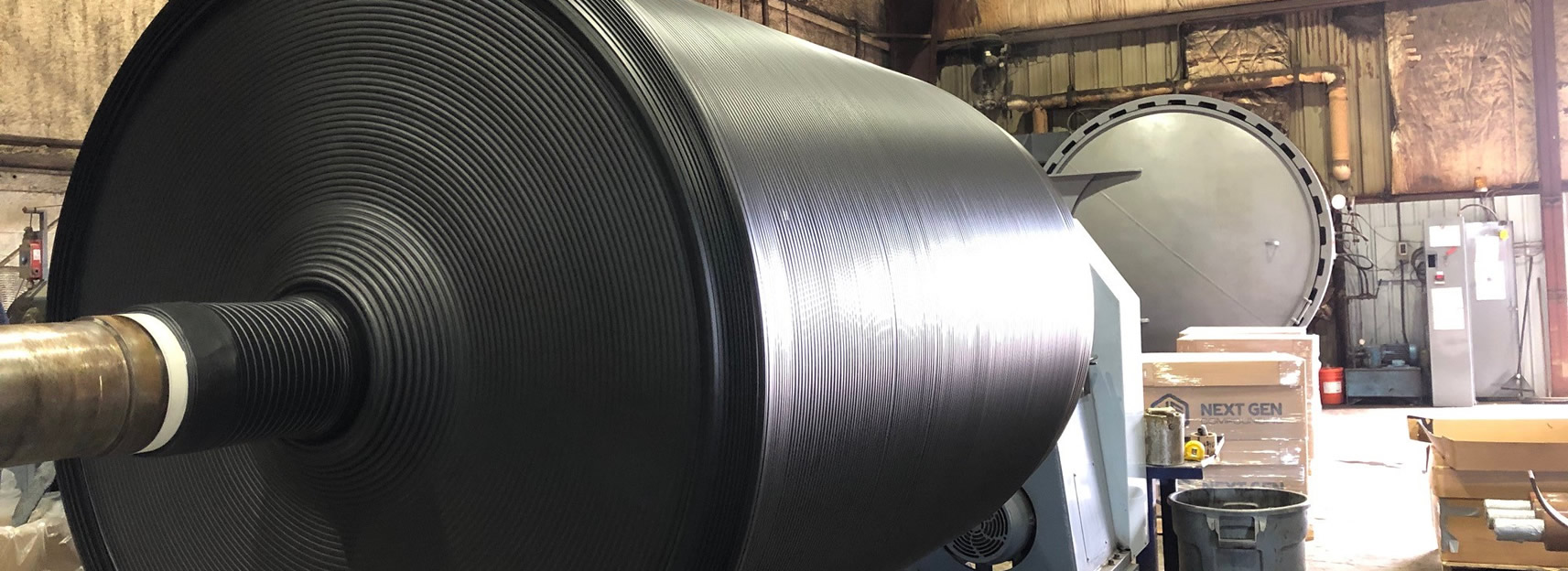

Steel Grit Recycling Blast Units

- More efficient and cleaner blast

- Reduces generated waste by 98%

- Less dust generated during blasting operations

- Safe for lead removal

- Can be combined with automated blast equipment to eliminate containment and reduce waste and cost

Rigging, Containment and Access Equipment

- Ability to rig, access and contain any type of structure (ie. Bridges, dams, elevated water tanks, container cranes, silos and stacks

Message Boards and Water Barriers

- A fleet of message boards and water barriers for all types of lane closure and traffic control requirements

Heavy Transport Equipment

- Blastco owned and maintained heavy transport equipment for rapid deployment to job sites anywhere in the United States

Services

Field Blasting & Painting Contractor Services

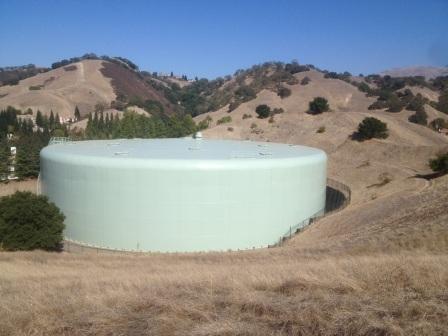

BLASTCO performs both new and maintenance field protective coating and lining applications for the industrial sector throughout North America. Our experienced teams are also able to undertake overseas projects.

Each of our teams has the equipment, personnel and project management experience to successfully complete any field protective coating project safely, on schedule and in complete compliance with local, state and federal environmental and safety regulations. We are frequently appointed as the general contractor to oversee all aspects of the project, allowing the customer to have a single point of contact throughout the job.

The efficiency of each team's organization is proven through a successful history of lead removal projects, which often become tedious and time consuming tasks. By using our in-hous designed containment enclosures and the latest technology for industrial coating application and surface preparation equipment, we have been able to decrease the labor required to setup and clean-up in the field for each lead removal project.

BLASTCO stands out in the field abrasive blasting and coatings industry not only because of the AMPP, NACE & AWWA certified quality that is guaranteed; but, also due to being recognized as a QP1 & QP2 certified contractor (CA#767974).

Adding to BLASTCO'S success is the relationship with Blastech and Tarsco, all under the TF Warren Group of companies.

HS & E

Health, Safety and Environment

BLASTCO has demonstrated the ability to operate in a safe and conscientious manner to preserve its employees, the environment and the surrounding community.

Field work requires more planning and organization as each job site is different. Trained supervisors and management oversee job setup and progression to ensure each day functions as safely as possible. BLASTCO stresses the importance of safety for each employee and the surrounding environment to ensure both are in the same healthy condition as before the job began.

We ensure this through our attention to detail, thoughtful policies and in-depth training. We strongly believe that training and awareness are essential for employees to function as a team to keep the workplace safe and accident-free.

Training & Certifications at BLASTCO:

- Initial and annual training

- CPR/First Aid

- Fall protection

- Confined space training

- Forklift certification

- Lockout-Tagout training

- Lead certification

- Man lift training

- GHS (Haz-Com) training

- AMPP C-3 and annual C-5 training for all site supervisors

- AMPP Certified Application Specialist (CAS) superintendents

- QP1 & QP2 certification

- NACE certification

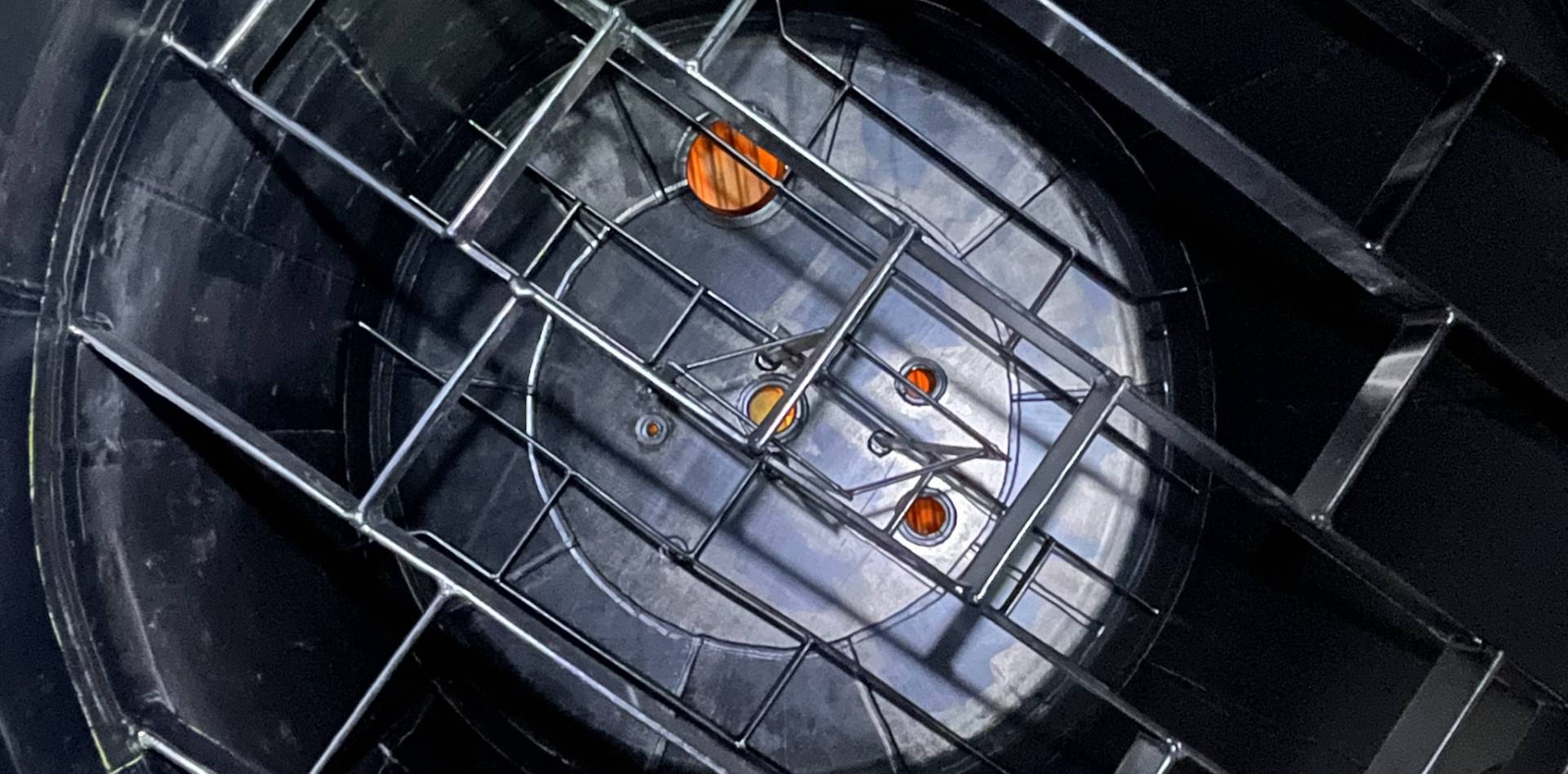

Lead Abatement

BLASTCO has a safe and efficient system for completing the complex requirements for successful lead coating removal on older structures. It requires testing before and after the job to ensure there has not been any lead contamination to employees or environment.

Samples are taken from the air and soil of the environment and the blood of employees to monitor the level of lead being exposed to each. With this constant monitoring, it is apparent when lead contamination is occurring and appropriate measures can be taken.

The containment contraptions are also heavily monitored to be immediately aware of lead contaminated material escaping. Site supervisors are required to shut down the site until the containment can be rectified.

As always, results are heavily documented to trace BLASTCO'S health, safety and environmental responsibility.

Corporate Safety Message

TF Warren Group senior management involvement is crucial to the success of our safety program. To that end the TF Warren Group Safety Management Committee has been formed. The committee, under the direction of the TF Warren Group Corporate Director of Health & Safety, is comprised of TF Warren Group senior management representatives and also includes the President/CEO.

Committee members confer weekly to establish and develop means of promoting and encouraging overall safety awareness and compliance within all of the TF Warren Group companies. This includes review of all H & S related incidents, standardization of safety policies, procedures, & reporting, ensuring adherence to health and safety regulations, safety training, and provision of adequate resources to sustain a successful safety culture and program.

Documenting and evaluating safety performance facilitates the recognition and acknowledgement of successful safety achievements: all with the common goal of striving to eliminate workplace illnesses and injuries within the TF Warren Group family of companies. Through awareness and cooperation we strive to achieve this goal.

Dan Milford, Corporate Director of Health & Safety – TF Warren Group