About Blastech Mobile

Our Solutions

Blastech Mobile has the most advanced plate processing operation currently available in North America.

Coupled with our Total Plate Processing facility and our Premium Plate business unit we are able to offer customer procured, hot rolled carbon steel plates directly through our partner SSAB who produce the high quality hot rolled carbon steel plate at their mill on the same site. We also process customers supplied steel plates.

We evolve

The entire facility is ISO 9001 certified and all tasks are carried out with safety and quality as our highest priority.

From our Mobile Alabama site, we are able to offer the following services:

- Steel plate blast and primed with globally recognized inorganic weldable primers. (See REDI-PLATE for details)

- Steel plates primed on one side with conventional high film primers typically organic and Inorganic zinc primer at thickness up to 4 mils and other high build technologies up to 6 mils dry film thickness.

- Steel plates which are blasted and then preserved with our unique clear transparent oil free chemical treatment which will preserve the condition of the surface in interior environments. (See CPP treatment for details)

Following the coating we are able to cut, burn, roll and bevel the plates to our customer’s drawings and specifications at our adjoining Total Plate processing shop. The processed material can be transported by truck or rail directly to the customer’s destination for immediate use.

REDI-PLATE™

As coating professionals Blastech developed the REDI-PLATE™ Process to ensure that every facet of the plate coating process was carried out to the highest global standards.

Plates incoming to the facility are checked for conformity to bills of lading, on approval each plate is entered into the custom built Blastlogix data management system where they permanently reside.

As plates are loaded onto the conveyor they are examined for surface contaminants and if present removed to meet SSPC SP 10 NACE 2 Surface Preparation Specification.

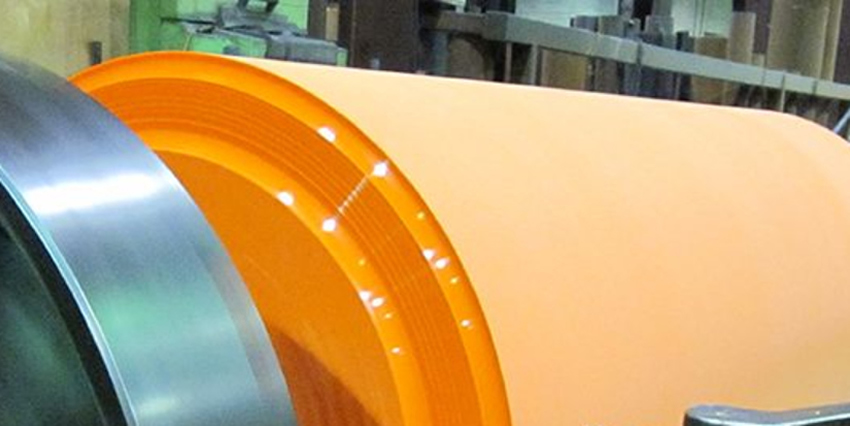

The plate enters an enclosure where both top and bottom surfaces are simultaneously impinged with a mixture of steel grit and shot to both remove the mill scale and impart a dense sharp profile that will support the adhesion of the coatings that are required to protect the steel from corrosion.

The plates are then heated to ensure drying times.

After blast cleaning the plate are examined for quality and major surface defects and to ensure steel is free from dust. Following which they are checked for the important blast profile. This data is recorded in the Blastlogix system.

Next stage is to apply the special inorganic coating uniquely formulated to be safely welded without noxious fumes and good weld quality.

The special application equipment is custom built to Blastech’s specifications. The reciprocating spray guns are calibrated to ensure the industry agreed standard dry film thickness of 0.6 – 0.8 mils (15 – 18 microns) is evenly applied over the entire surface. Dry Film Thickness is verified by attaching smooth panels to both sides of the plate on entry to the coating module then measured after drying. The panel are retained and measurements are recorded in the Blastlogix data base. We retain independent reports for each and every plate we process in our data base for both commercial and technical issues that may arise in the future.

After coating the information entered into Blastlogix at the start of the process, the plate is re-identified using a state-of-the-art marker with all traceability components the plates are re marked with the original markings plus any other information required by our clients before entering a drying tunnel to ensure that no damage occurs when lifting by magnets into positions for intermediate storage prior to order assembly and loading.

We have recently extended our REDI-PLATE™ process to comply with industry demands for the application of high build coatings to the top (exterior) surfaces of the plates.

After the abrasive cleaning to specification and before entering the coating module we create a nominal 4” bare area around the plate to facilitate later processing such as burning and welding.

In the coating module we apply the specified coating to the thickness required. Dry Film Thicknesses are verified and recorded.in our Blastlogix plate management system.

The plates are carefully stored with airspaces to allow for curing to ensure that shipping damage is minimized.

After curing the plates are shipped by truck or rail.

Benefits of REDI-PLATE™

- Process is carried out in custom built controlled industrial environment.

- Plate surface is inspected providing major defect free steel is delivered to job site.

- Provides specified profile for application of weldable primer and subsequent costs, saving cost of post-fabrication blasting.

- Improved coating system performance.

- Reduces corrosion rate prior to finishing.

- Saves the cost of weld splatter removal.

- Minimizes cost of surface preparation after fabrication.

- Potential for reduction of incoming inspection costs.

- After suitable preparation virtually type of protective coating can be directly applied.

Clear Plate Preservative (CPP)

The process follows the identical method used for REDI-PLATE™ until the plates reach the coating stage and at that time after inspection the freshly blasted steel is treated with a special oil free preservative in order to retain the surface preparation.

After treatment the plates are remarked using the Blastlogic data.

The plates are then conveyed to the unloading position via a heated tunnel.

Benefits of CPP

- The process is carried out in custom built controlled industrial environment.

- The plate surface is inspected to ensure no major steel defects are shipped.

- The processed plate can be processed as clean steel including high speed welding, laser cutting etc.

- As the processed plates are only suitable for brief periods of exterior weather exposure transportation requires that the loads are fully protected. However, they may be stored indoors for up to year.

- The plates may be coated after process with a large variety of industrial coatings including powders however confirming tests should be carried out to verify compatibility.

About Blastech Plate Services

Our Solutions

Blastech Plate Services has been processing steel plate for more than 35 years. Raw carbon steel plate is delivered to us by road and rail. We routinely offer blast cleaning to remove mill scale with the ultimate goal of providing an SP10 Near white metal surface. After blasting we can apply weldable primer (Redi-Plate) or clear plate preservative (CPP) to protect the plates prior to cutting, welding, and shaping. Our blasting and weldable primer application provides a clean, protected surface for fabrication of small cut parts or large tank wall sections and roofs. This saves time and money in the field with further application of coatings. The expensive process of blasting in the field is also eliminated.

We Evolve

Blastech Plate Services has become an industry leader in surface preparation and coating application by enforcing strict quality assurance measures through our internal policies and in accordance with AMPP Standards.

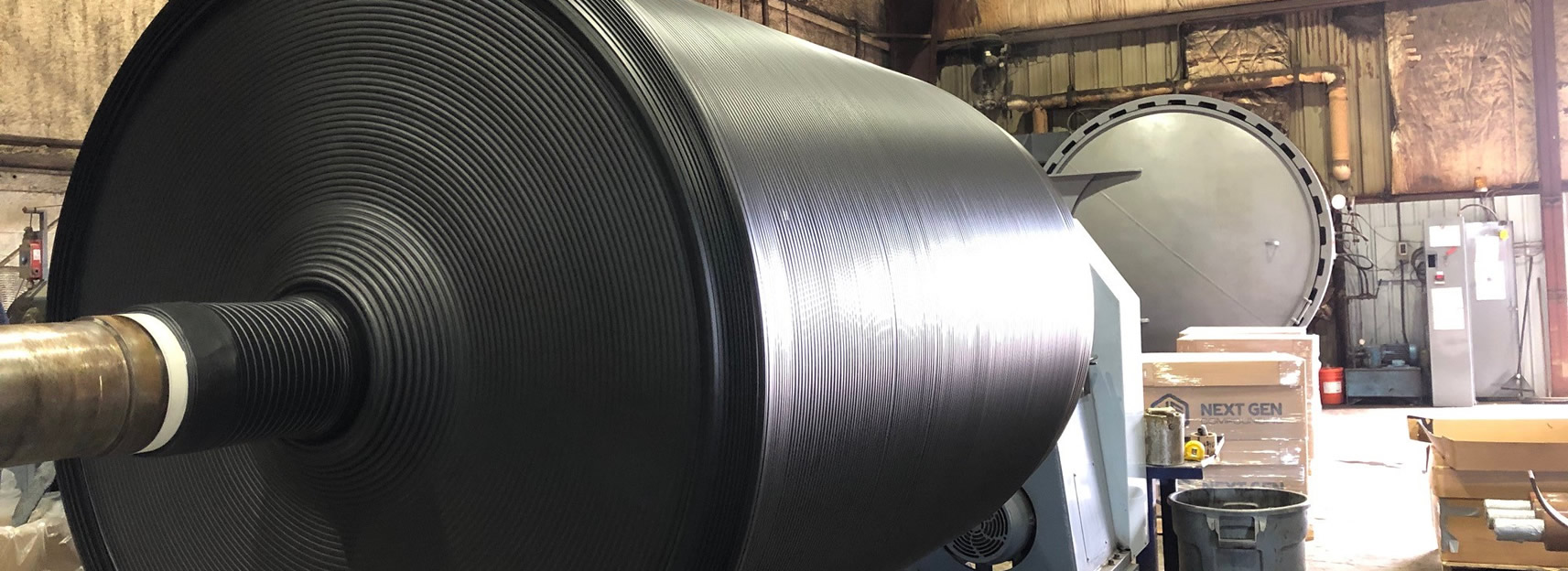

Much like our Mobile Alabama facility, we have a finely tuned automated conveyor line that blasts and coats steel plate to exact specifications.

We strive to build long term relationships with our customers based on accurate scheduling, in-depth quality monitoring and competitive pricing.

Facilities

Our facility is located in Brantford Ontario on a 20-acre site, within minutes of Highway 403

- Located on rail siding CN FE47

- Outdoor mobile crane capacity up to 30 tons

- Indoor crane capacity up to 20 tons

- Fully automated conveyor line system

Why Employ Blastech?

- Largest automated blast and coat conveyor line in Canada

- Quality surveillance by certified NACE & AMPP Inspectors

- Quickest turnaround time in the business

- Outstanding customer service

Industries We Serve

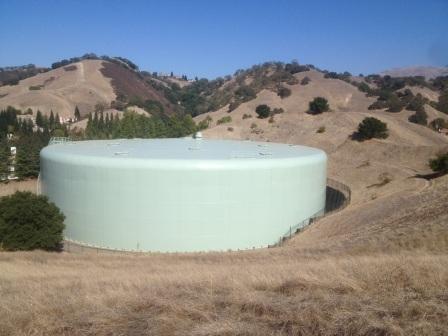

- Chemical and Water Tank Builders

- Industrial Manufacturing

- Jet Fuel Storage

- Petroleum Refining

- Mining and Mineral Processing

Our Services Include

- Surface Preparation to exacting specifications

- Coating application to exacting specifications

- Stenciling for traceability

- Detail Quality documentation for all loads

- Project specific packaging if required

- Freight

REDI-PLATE™

As coating professionals Blastech Plate Services developed the REDI-PLATE™ Process to ensure that every facet of the plate coating process was carried out to the highest global standards.

Benefits of REDI-PLATE™

- Process is carried out in custom built controlled industrial environment.

- Plate surface is inspected providing major defect free steel is delivered to job site.

- Provides specified profile for application of weldable primer and subsequent costs, saving cost of post-fabrication blasting.

- Improved coating system performance.

- Reduces corrosion rate prior to finishing.

- Saves the cost of weld splatter removal.

- Minimizes cost of surface preparation after fabrication.

- Potential for reduction of incoming inspection costs.

- After suitable preparation virtually type of protective coating can be directly applied.

Clear Plate Preservative (CPP)

The process follows the identical method used for REDI-PLATE™ until the plates reach the coating stage and at that time after inspection the freshly blasted steel is treated with a special oil free preservative in order to retain the surface preparation.

After treatment the plates are remarked using the Blastlogic data.

The plates are then conveyed to the unloading position via a heated tunnel.

Benefits of CPP

- The process is carried out in custom built controlled industrial environment.

- The plate surface is inspected to ensure no major steel defects are shipped.

- The processed plate can be processed as clean steel including high speed welding, laser cutting etc.

- As the processed plates are only suitable for brief periods of exterior weather exposure transportation requires that the loads are fully protected. However, they may be stored indoors for up to year.

- The plates may be coated after process with a large variety of industrial coatings including powders however confirming tests should be carried out to verify compatibility.

About Total Plate

Our Solution

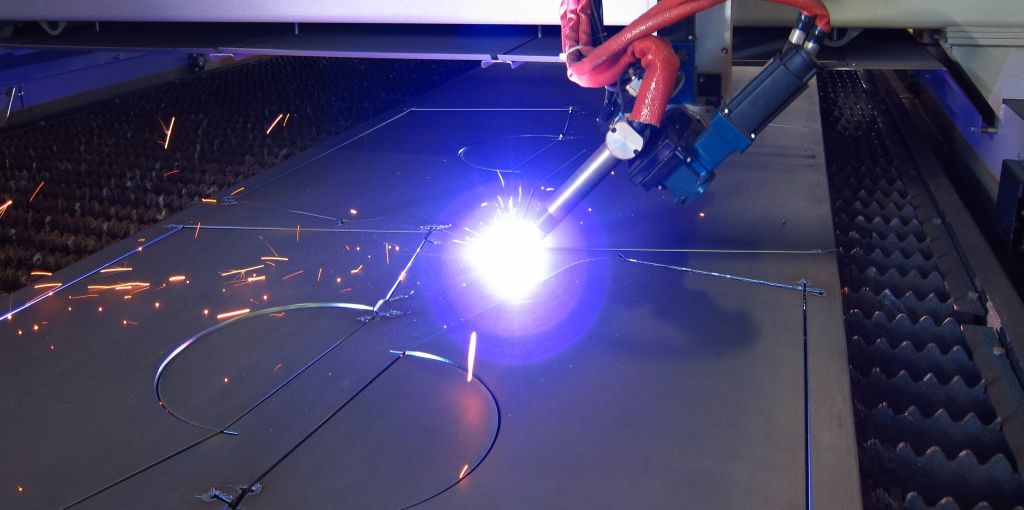

The TF Warren Group opened a premier plate processing facility at an Alabama steel mill called Total Plate Processing. This facility specializes in burned, beveled, and rolled plate primarily to service the ground storage tank industry. Total Plate’s facility is equipped with a high speed, high definition plasma burning table and state of the art plate rolls. In addition to the industry leading blast and prime service currently offered by Blastech Mobile, Total Plate’s strategically located site can now provide enhanced cost savings associated with transportation and processing.

TF Warren Group is now able to offer a variety of different shop coatings, burning capabilities up to 2” thick, and rolled plates of all thicknesses up to 1.5” x 120” wide and 600” long. Total Plate’s 45,000 sq. ft. custom-built facility is equipped with state-of-the-art High-Definition Plasma compound beveling heads, an 88’ dry downdraft table, and a sophisticated 4-roll plate rolling system with tilting in-feed and out-feed tables to ensure repeatable, accurate, and low cost part production.

Total Plate has recognized the need to further service the tank industry by offering the ability to form parts associated with tank construction. When we expanded our operation in 2019, we added 25,000 square feet to our existing facility. This not only allowed for additional burning and rolling capacity, but also the ability to add a press brake to provide a more complete package to our services. Total Plate can now offer the tank market fabrication of pontoons, bulkheads, inner/outer rims and windgirders, as well as any other parts that need forming.

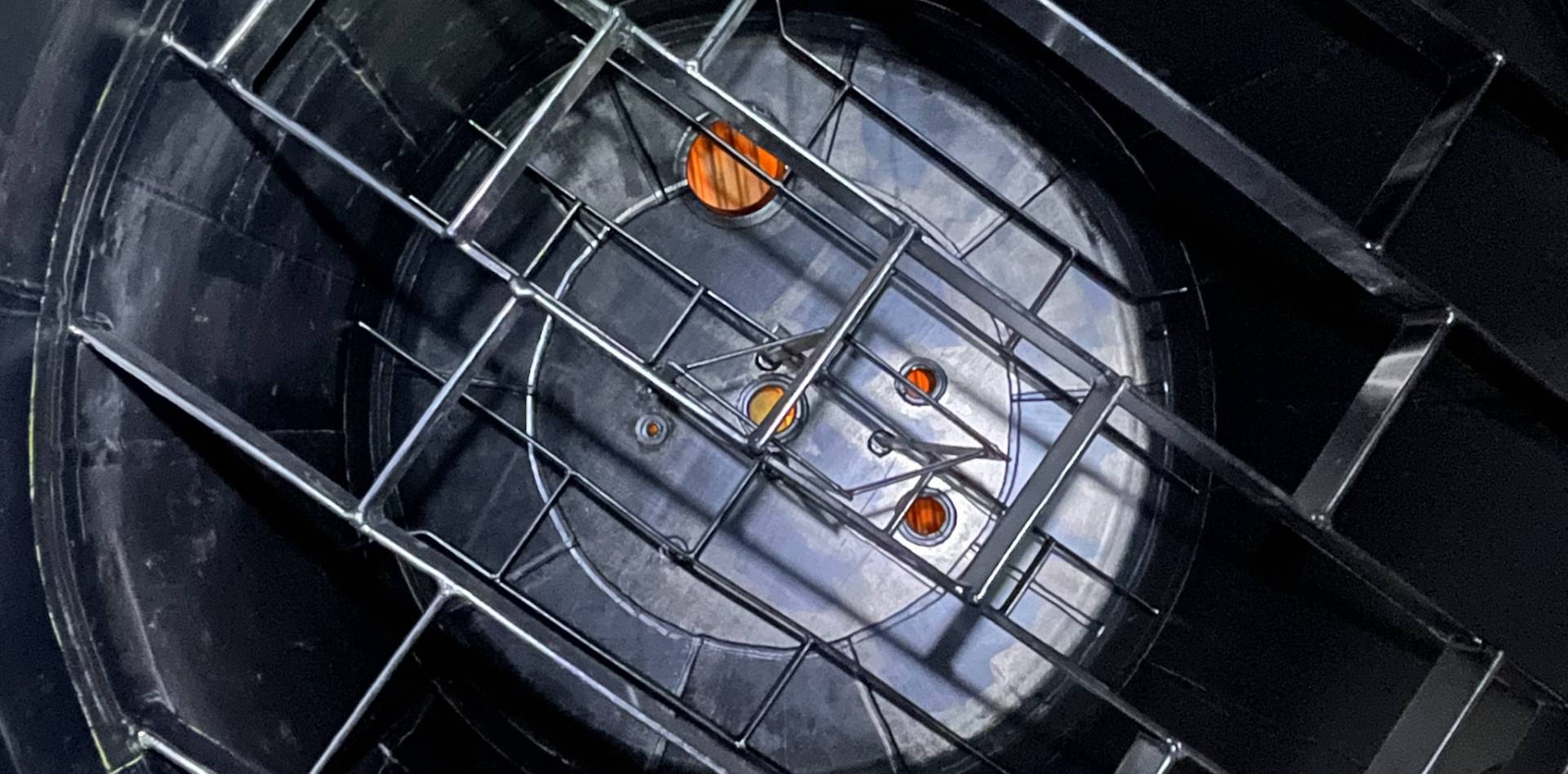

About Blastech Rail

Strategically located in southern Ontario in Canada, Blastech Rail Services, a TF Warren Company, is a trusted source for qualification and maintenance of tank cars.

We are AAR M1003 certified to M1002 requirements.

Along with full mechanical repairs, we offer complete rubber and liquid coatings qualifications. We are easily accessible by CN Rail, siding reference is CN, FE 47.

Blastech Rail Services has continued to expand their facility and our skilled craftspeople to meet customers’ demands for a fast turnaround of the requalification process including inspections, repairs and complete relines. Being the only AAR certified tank car facility in Canada, that performs rubber lining work, our experienced lining department can perform lining repairs or full replacement of both liquid and sheet linings to the industry’s highest standards.

We recently started an expansion project that will consist of 3 phases. The first phase has been completed and we have added more than a 1,000 feet of track to our site which now provides more tank car spots for our customers. We are planning to expand even further by adding more track, a second transfer table and a return line for completed cars. We have also invested in a Robotic Stripping Machine for the removal of old rubber linings. This will be an integral part of maintaining speedy turn times while providing a safe environment for this type of work. We anticipate commissioning of the unit by the fourth quarter of this year.

We are active members of NACE and AMPP. Our coatings and linings are applied to meet or exceed recognized international and customer’s standards of surface preparation and application.

Our safety vision is directed by our President and senior executives and we are dedicated to maintaining the health and safety of our employees, subcontractors, customers and the public.

Download Certificate

Download Certificate