Publications

The following are the main company publications.

Contact

-

City of Houston Above Grade Crossings Article

Download PDF -

Coatings Pro Four Points Article

Download PDF -

Nov 2016 CoatingsPro Blastco article

Download PDF

Our Solutions

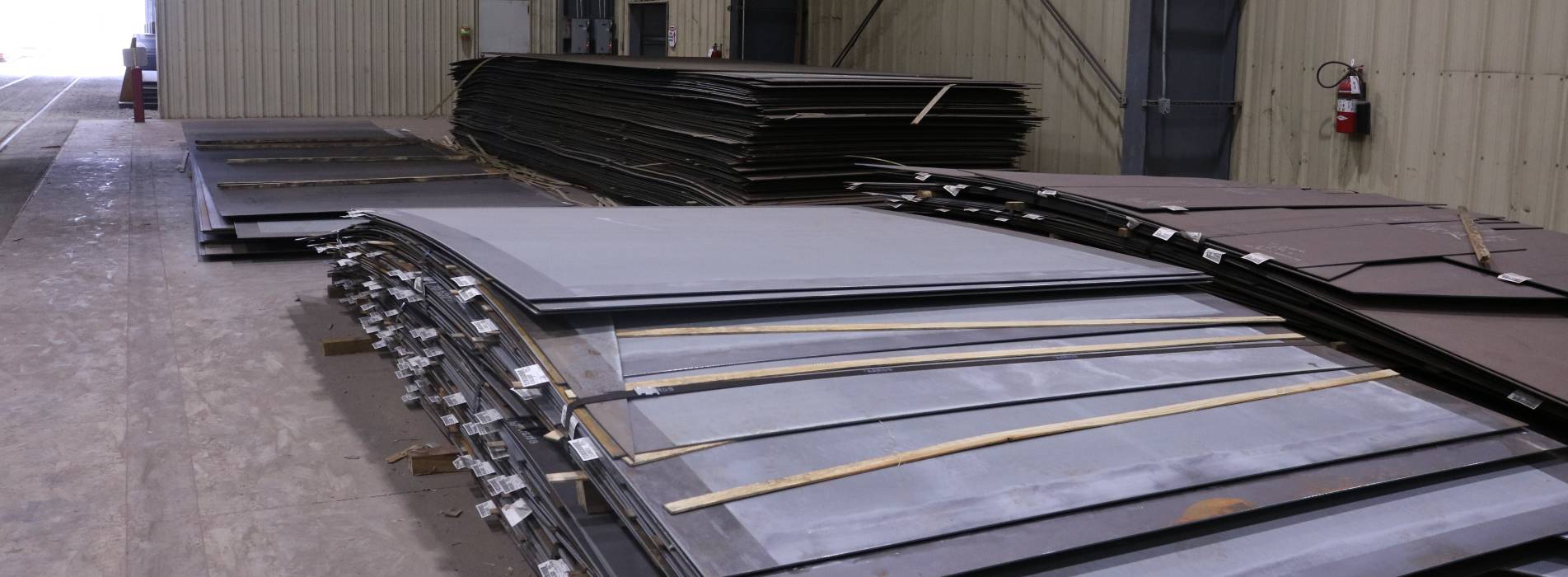

For years, Blastco has gained credibility through its strong presence in the refinery industry as a new construction and maintenance field abrasive blaster and applicator of protective coatings.

Blastco's history for high performance coatings began with field applications for aboveground water storage tanks. After years of quality service, Blastco expanded into other more complex fabrications and coating systems such as petro-chemical tanks, bridges and dams.

We evolve

Blastco utilizes the latest technology, including paperless documentation software, ensuring quality control on every project. Each project follows a designed workflow, a systematic approach to documentation regulation and reporting cascading from top to bottom. Integrating the latest technology has streamlined project management, communication, and increased efficiency.

And improve

The most carefully considered decision made when buying or repairing a steel storage tank should be the one that determines the quality of its coating. Preserving and maintaining surfaces on steel storage tanks are crucial for increasing structural longevity and safeguarding the investment.

Regardless of the type or scale of the project, Blastco is self-sufficient for all aspects of new, maintenance and repair work for field surface preparation and coatings & linings applications.

Capabilities and Services

- Shop and field applications

- Conformance to UFGS Specifications

- Conformance to EM 385 (safety requirements)

- Lead abatement

- AMPP QP-1, QP2-1, and QS-1 certified

- Storage tank construction and repairs

- Mechanical and coating repairs

- Fireproofing

Why employ Blastco?

- NACE certified coating inspectors

- Personnel and facility to complete any size project

- Shop and field work capability

- QP-1, QP-2 & QS-1 certified contractor

- Certified members of AMPP and AWWA

- Impeccable safety records

- In-field lead abatement/removal capabilities

Industries Served

- Terminals

- Pipeline

- Petroleum Refining

- Water & Wastewater

- Chemical Processing

- Alternative Fuels

- Industrial Manufacturing

- Transportation

"Blastco sets the mark very high when it comes to quality of work and worker safety. Blastco is a certified contractor for quality of work and hazardous coating abatement in accordance with NACE and SSPC and they follow the requirements of AWWA when it comes to construction and painting of steel water tanks. This in itself makes Blastco a premier coating contractor. I look forward to many more years of having Blastco on my projects as I know when they are on my projects, without question the job will be done right."

Robert Boswell - CEO / Principal Professional - Round Rock, Texas

"Please accept our sincere appreciation for a job well done. Blastco has proved itself to be a company of integrity, taking on the challenge to grind forward on this project, overcoming multiple obstacles and weather delays, in order to reach completion. Blastco succeeded in not only completing on time, but completing ahead of schedule. Komada was particularly impressed with Blastco’s ability to use lessons learned from Hangar 3741 and apply them to Hangar 3741 and complete that hangar quickly and with excellent quality. Again, thank you. Komada looks forward to working with Blastco again whenever the possibility arises."

Rick Kincaid - Area Construction Manager in Komada LLC

"AECOM wishes to express our sincere appreciation for the services that have been provided by Blastco on numerous ground storage and hydro tank recoating projects. Blastco’s attention to detail and quality is commendable. We will enjoy working with Blastco on future projects."

Bruce Baumel - Senior Construction Manager in AECOM

Automated Blast Equipment

- Clean blast with no dust or contaminants left on substrate

- Eliminates the need for containment

- Less hazardous for surface preparation crews and surrounding community

Industrial Vacuums

- Fast clean up

Dehumidification Units

- A fleet of DH equipment from 2250 CFM to 10,000 CFM readily available

- Units maintained to meet or exceed dehumidification specifications to provide high quality surface preparation for a better end product

Generator Units

- A fleet of generator units from 5KVA to 180KVA readily available

Steel Grit Recycling Blast Units

- More efficient and cleaner blast

- Reduces generated waste by 98%

- Less dust generated during blasting operations

- Safe for lead removal

- Can be combined with automated blast equipment to eliminate containment and reduce waste and cost

Rigging, Containment and Access Equipment

- Ability to rig, access and contain any type of structure (ie. Bridges, dams, elevated water tanks, container cranes, silos and stacks

Message Boards and Water Barriers

- A fleet of message boards and water barriers for all types of lane closure and traffic control requirements

Heavy Transport Equipment

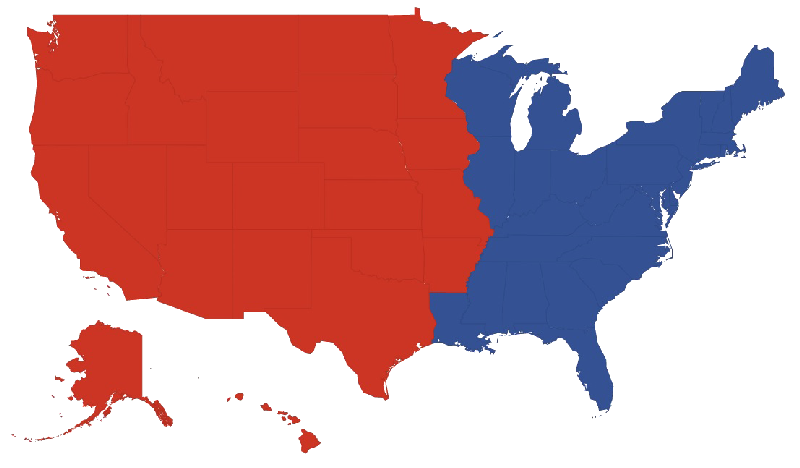

- Blastco owned and maintained heavy transport equipment for rapid deployment to job sites anywhere in the United States