Carlos Gutierrez is Attending the Argus Crude Summit in Houston Feb. 15-17, 2023

Carlos Gutierrez with Tarsco is attending the Argus Americas Crude Summit February 15-17 in Houston, TX. A full service provider, Tarsco specializes in above ground storage tank construction, repair and maintenance services to industries such as terminals, pipeline, petroleum refining, LPG, alternative fuels and chemical processing. Contact us today at (832) 299-3200 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.

REDI-PLATE™ Is Cost Effective and Environmentally Responsible

REDI-PLATE™, the abrasive cleaning and coating of steel plate with specially formulated inorganic pre-construction primers prior to fabrication, is cost effective and environmentally responsible. Blastech partners with steel plate producers and steel distributors to offer REDI-PLATE™ throughout North America. The fully automatic process prepares the plate to SSPC SP 10/ NACE No. 2 surface preparation specifications to produce a sharp dense profile of 1.5 - 2.5 mils. The many benefits of using REDI-PLATE™ include reducing the need for post fabrication blasting by as much as 80%, eliminating VOC costs, improving coating system performance, reducing corrosion rate prior to finishing, and minimizing the cost of surface preparation after fabrication. Contact us today to learn more at (251) 328-4110 or visit our website.

At Total Plate's Processing Facility We Can Fabricate Various Components with Our Press Brake

At our Total Plate Processing facility, we specialize in burned, beveled, and rolled plate primarily to service the ground storage tank industry. Total Plate’s facility is equipped with a high speed, high definition plasma burning table and state of the art plate rolls. Our 20’ x 500 ton capacity press brake is capable of bending common grades of steel plate, has high stroke and daylight for deep box/panel bending and 18” throat depth to utilize full length. Total Plate can fabricate components for pontoons, bulkheads, inner/outer rims and windgirders, as well as any other parts that need forming. Contact us at (251) 328-4110 or visit our website to learn more.

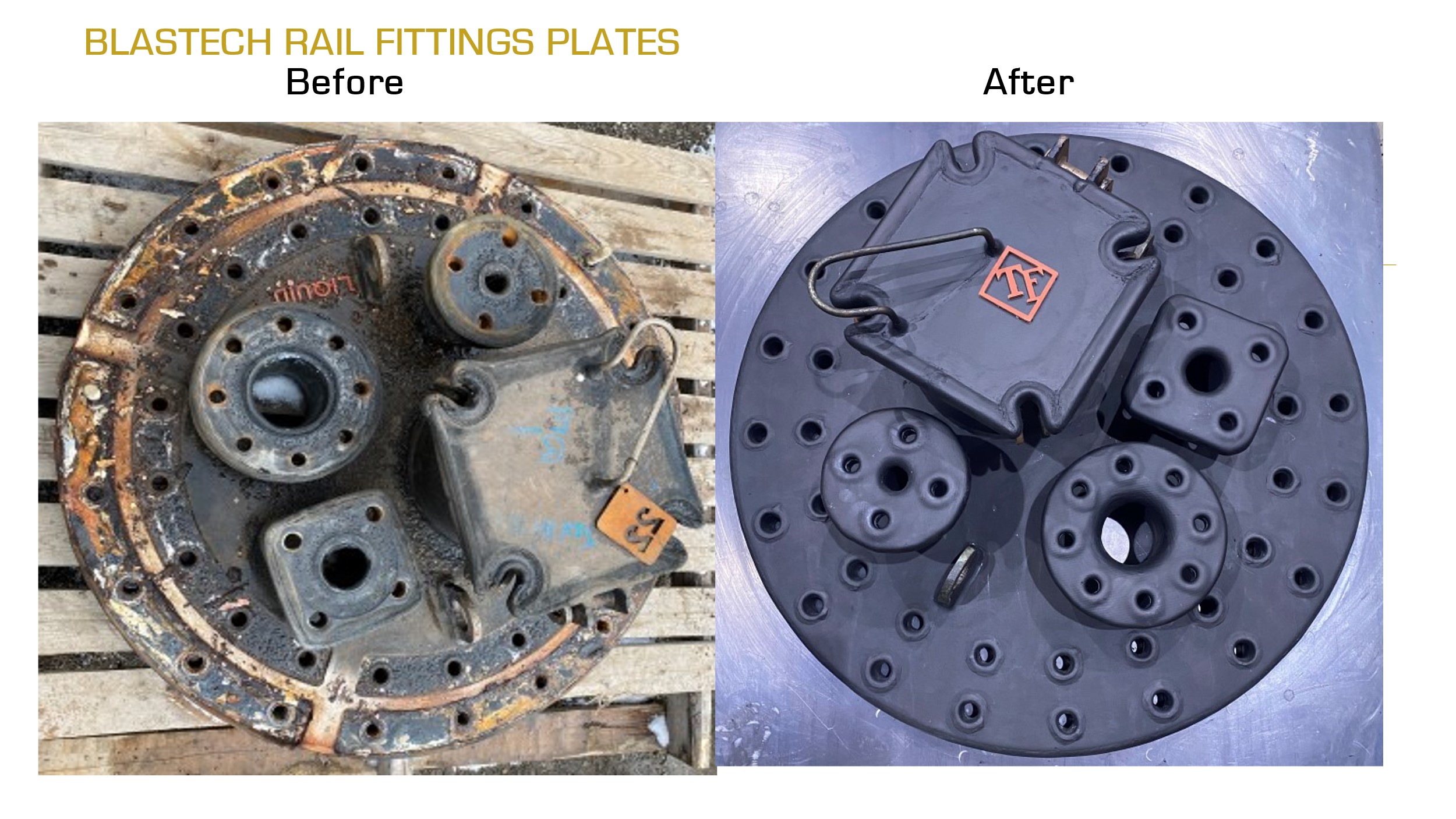

Blastech Rail Services Requalifies Tankcars on 5 Year Intervals

Blastech Rail Services requalifies Tankcars on 5-year intervals. This includes all mechanical requirements, interior linings, and exterior coatings. The top fittings plates are routinely stripped of the existing rubber and recovered to manufacturers specifications. Our skilled applicators perform this work to the highest quality standards. Call Derrick Hexamer at (519) 861-0072 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.

Tarsco Completes Five API 650 Tanks for Client in Texas

Tarsco completed this terminal expansion for a client in Texas that included the engineering, procurement, fabrication, and construction of five API 650 tanks. The scope of work consisted of (2) 50,000 barrel diesel tanks, (3) 30,000 barrel MTBE tanks, and (1) 150,000 barrel fuel oil tank. Due to record rain fall at the job site and the expedited schedule, our crew still completed the job on time. At Tarsco, we can provide greenfield projects as well as expansions and retrofits to existing import and export or storage terminals. Contact us today at (832) 299-3200 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.