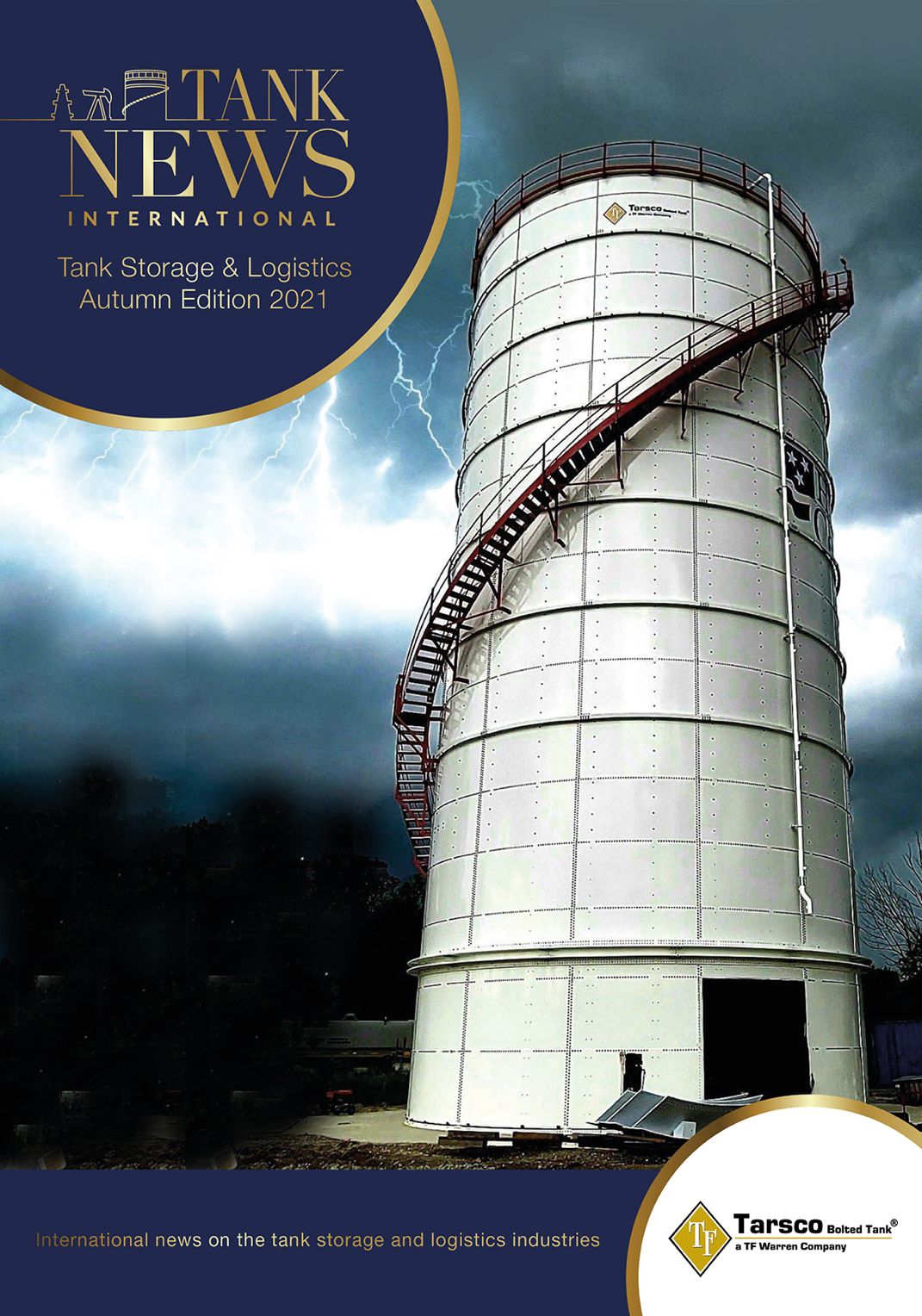

Tarsco Bolted Tank Featured on the Cover of Tank News International Autumn Edition

Tarsco Bolted Tank is featured on the cover of the Tank News International Autumn Edition. This industrial silo completed in Ohio is being used to store 4,000 tons of cement. Whether dry or liquid storage, Tarsco Bolted Tank can provide a comprehensive range of products such as epoxy coated, stainless steel and glass fused to steel tanks. Contact us at (866) 700-2500 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.

Total Plate Processing Provides Plasma Cutting, Beveling, Rolling and Forming to Customers Requirements

Total Plate Processing can provide high definition plasma cutting, beveling, rolling and forming to your unique requirements. We are capable of burning plate up to 2” thick, and rolling plates of all thicknesses up to 1.5” x 120” wide. Our custom-built facility expanded to double its capacity and is equipped with high definition plasma compound beveling heads, an 83’ dry downdraft table, and a sophisticated 4-roll plate rolling system with tilting in-feed and out-feed tables to ensure repeatable, accurate, and low cost part production. Contact us at (251) 328-4110 or visit our website to learn more about all the processing capabilities available at Total Plate.

Tarsco Bolted Tank Applies Powder Coating to the Industry's Highest Standards

Tarsco Bolted Tank utilizes a custom designed, continuous automated coating line able to apply powder coatings to the industry’s highest standards. We pre-program each coating application before each project and can take on challenging shapes for various parts up to 48” wide and 84“ high and 25’ long and weighing up to 12,000 lbs. The application booths are designed for quick color changes to facilitate customer requirements and a wide range of powder coating products. Contact us at (866) 700-2500 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.

Brant Corrosion Control Completed the Metalizing on This Large Pressure Vessel

Did you know that metalizing, when applied correctly, can last 30 to 40 years in certain environments? Brant Corrosion Control recently completed the exterior metalizing of this large pressure vessel. Next, the exterior coating is subjected to a 24 hour water test to ensure complete coverage without premature rusting. At Brant Corrosion Control we are experts in the industrial application of protective coatings and linings for tanks, vessels, pipes, fans, agitators and other specialty fabrications. Contact Derrick Hexamer at (519) 861-0072 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.

Blastech Rail Services is a Trusted Source for Qualification and Maintenance of Tank Cars

Blastech Rail Services is currently working on the rubber lining inspections, repairs, and relines as part of a substantial tank car project for our valued customer. The cars that are deemed as “strip & reline” are interior stripped via 40,000 psi water blasting with our automated robot system, interior rubber lined, and exterior painted prior to shipping. Strategically located in southern Ontario in Canada, Blastech Rail Services is a trusted source for qualification and maintenance of tank cars. Call Derrick Hexamer at (519) 861-0072 or email This email address is being protected from spambots. You need JavaScript enabled to view it. to learn more.