Houston Manufacturing Facility

Krueger Engineering and Manufacturing's Houston facility spans 110,000 sq. ft. and is equipped to handle large-scale, complex projects for critical industries. Our facility is designed for efficiency, precision, and reliability, ensuring top-quality results for every project.

Contact

Capacities & Specifications

- Estimated Monthly Capacity: 800,000 pounds

- Maximum Diameter: 20 feet

- Maximum Weight (Single Item): 300 tons

- ASME Code Certified Section VIII, Division I

- TÜV Rheinland Inspection

Shop

- Approximate Working Space (Square Feet): 110,000 sq. ft. (inside shop), 27 acres (yard area)

- Type of Floor in Shop Building: Concrete

- Cranes: 15 gantry cranes, with up to 40 ton capacity, and 30’ hook height

Manufacturing Equipment

Welding Equipment

- 15 AC, 50 DC with current range 200-1500 amps

- 8 manual, 10 power welding positioners

- 28 manual, 20 automatic turning rolls

- 5 Lincoln manipulators ML2 automatic welding machines

- 5 Holbert automatic tube welders

- 4 Linde Heli-arc inert gas welders

- 2 National Cylinder Min-arc

Machine Tools

- (2) Radial drills, 77" reach, 18" column, 3" maximum drill size

- (1) Radial drill, 96" reach, 18" column, 3" maximum drill size

- (1) Radial drill, 144" reach, 30" column, 4 1/2" maximum drill size

Miscellaneous Equipment

- Cladding / Overlay Capability

- 16" flex wheel Dewalt saw

- Multiple iron workers up to 130 ton capacity

- Plasma arc (1) PAC-45, (1) PAC-10

- 15' x 15' Manipulator w/Tandem Arc

- Multiple Weld Positioners up to 8’ diameter

- Quickmill 120" CNC (120" OTC x 30" THK, Table Size 142" x 162")

- Quickmill 96" CNC (96" OTC x 30" THK, Table Size 115" x 138")

- 6” x 6” x 1” Roundo Angle Roller

- 90’ x 10’ Alltra Plasma Cutting Table

- Hydmech V-18APC Automatic Tilt Frame Vertical Bandsaw

- Multiple pipe cutting & beveling machines up to 36” diameter

Heat Treating

- Onsite Heat treating capabilities

Testing & Inspection

- Radiographic & PAUT inspection

- Normal maximum hydrostatic test pressure - 10,000 psig, 2,500 psig pneumatic

- Non-destructive testing available: halide, magnaflux, dye penetrant, mass spectrometer

Materials and Thickness

| Material | Max Thickness | Min Thickness |

|---|---|---|

| Carbon Steel | 7" | 3/16" |

| Nickel | 3" | 1/8" |

| Nickel Clad | 3" | 1/8" |

| Nickel Alloy | 3" | 1/8" |

| Stainless Steel | 3" | 1/8" |

| Low Chromium Steels | 3" | 3/16" |

| Nonferrous | 3" | 1/8" |

| Copper | 1" | 1/8" |

| Everdure | 1 1/2" | 1/8" |

| Aluminum | 3" | 1/8" |

| Monel | 3" | 1/8" |

| Hastelloy | 1 1/2" | 1/8" |

| Aluminum Bronze | 1 1/2" | 1/8" |

| Incoloy | 3" | 1/8" |

Our Advanced Equipment

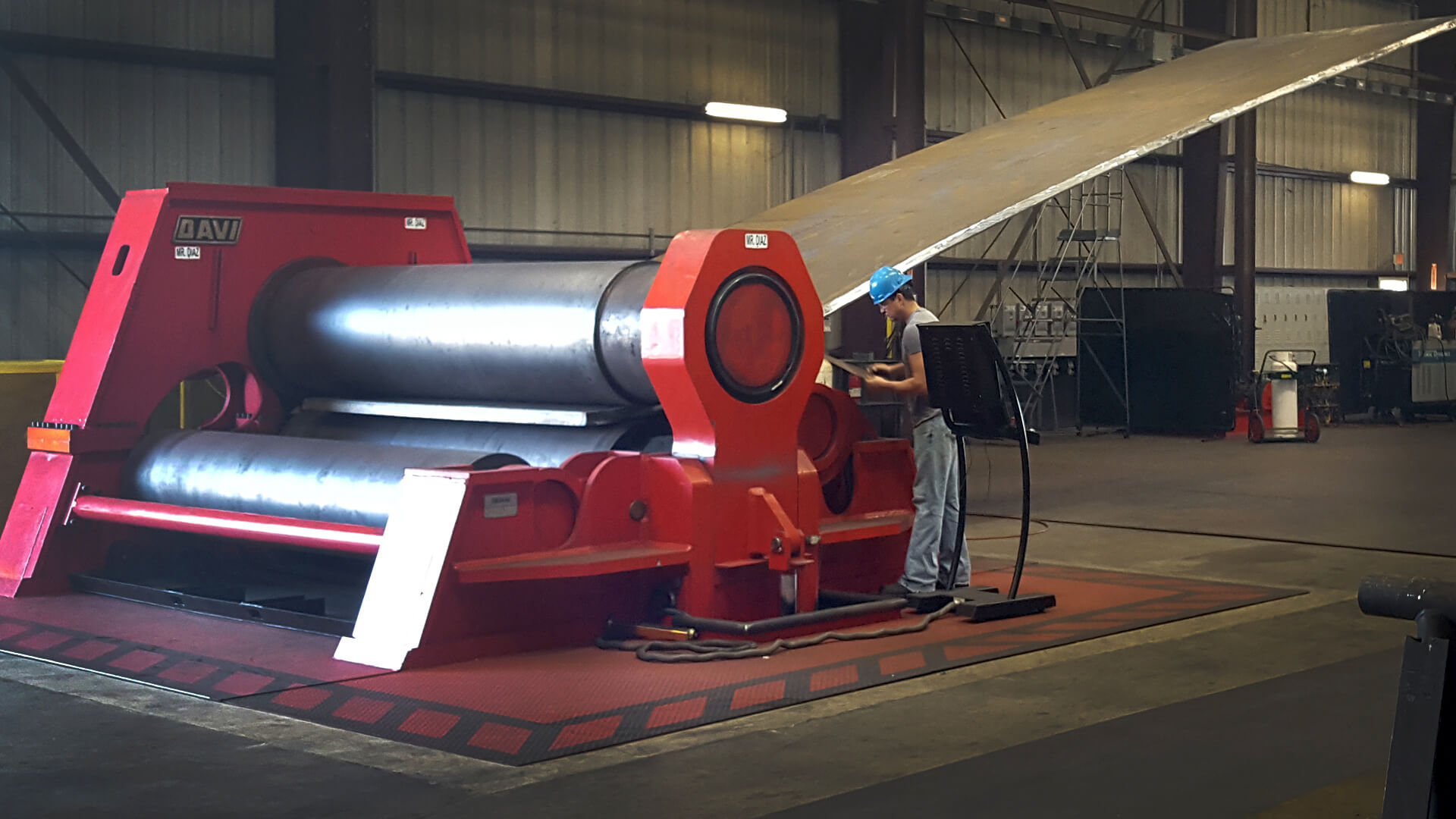

Davi Roller

Capability to roll steel up to 4" thickness and up to 10' in length for cylinders, rings, and segments.

PRESS 1250

1250 ton CNC Press Brake, forms up to 4" thick, 10' length, and 1" plate up to 22' length.

Crane

15 gantry cranes, with up to 40 ton capacity, and 30’ hook height.

Why Choose Our Houston Facility?

- Comprehensive in-house capabilities

- State-of-the-art equipment for large-scale projects

- Strategic location for fast domestic and international shipping

- Experienced, certified welders and fabricators

- Advanced quality control processes