About Duratech Systems

About Duratech Systems

Located in Redford, Michigan, Duratech Systems became part of the TF Warren Group in June 2021. This acquisition was a significant milestone for the group, enabling us to offer rubber lining services within the United States. Prior to this, all rubber projects were handled in Canada by Brant Corrosion Control, another TF Warren company.

For over four decades, Duratech Systems has been a leading rubber applicator in the U.S. Founded as a father-and-son business, we have grown substantially through our unwavering commitment to customer satisfaction and exceptional quality.

Our Solutions

Our team of professional applicators is skilled in lining pipe interiors, mixers, intricate components, and large API650 storage tanks. We perform these services both in our shop and on-site. Specializing in turn-key projects, we manage rubber removal, abrasive blasting, and relining, all managed to meet our customers’ schedules.

We have expanded our capabilities with a new roll shop, specializing in rubber and urethane roll coverings for steel processing facilities across the United States.

Why employ Duratech Systems?

- On-site rubber lining inspections and repairs

- Long history of successful projects

- Dedication to high quality

- Expert management and applicators

- Competitive pricing

- Contract maintenance service agreements

Industries Served

- Water & Wastewater

- Metals & Minerals

- Industrial Manufacturing

- Chemical Processing

- Food & Beverage

- Power Generation

- Steel Processing

What we do

Rubber Linings Shop & Field

Different applications require unique elastomers and Duratech Systems specialize in installing all of them. We work with our customers to meticulously evaluate the temperature, chemical composition and concentration of the conveyed materials to determine the optimal compound for their specific application.

- Natural Rubber Compounds:

- Soft natural rubber – good for abrasive environments and general-purpose chemical resistance

- Semi-hard – used in water treatment equipment and oxidizing/plating solutions. FDA compliant options are available

- Ebonite (bone-hard) – suitable for valves and piping systems

- Synthetic Rubber Compounds:

- Neoprene – excellent UV and ozone resistance for general purpose abrasion and chemical resistance.

- Chlorobutyl – good chemical resistance for most acids and caustics. FDA compliant options are available.

- Bromobutyl – superior temperature resistant to acids and caustic solutions up to 260°F

- Nitrile – use for oil tank linings or when hydrocarbons are present.

We excel in lining pressure vessels, over-the-road tankers, mixing equipment, and any storage or processing equipment requiring corrosion and abrasion protection.

Our rubber lining services are available both at our facility and in the field, ensuring the highest quality in the industry. We uphold the highest standards and are dedicated to protecting your most valuable assets.

For a detailed explanation of our on-site capabilities tailored for your project, please contact our office today.

Duratech Systems is an approved applicator for all major sheet rubber compounders, including:

- Polycorp (formerly B.F. Goodrich)

- Blair Rubber (formerly Goodyear)

- Rema Tip-Top

- Steuler – KCH

Industrial Roll Covers

We specialize in providing rubber formulations tailored for the steel and aluminum processing industries. Our commitment to exceptional customer service includes dedicated trucks for picking up your rolls and delivering them back once completed.

Duratech Systems Equipment:

- 12’ Dia. x 50’ Long Autoclave

- 54” Dia. x 54” Long Autoclave

- 15’ x 55’ and 24’ x 40’ Gritblast Rooms

- Portable Sandblasters

- Truck Fleet

- Cold Storage for Rubber

- 10-ton Overhead Crane

- 2-ton Overhead Crane

- Poreba manual lathe, swing over bed 32”, between centers 312”, Remco SH 1200 series medium speed profile grinder attachment

- Bertram manual lathe, swing over bed 26”, between centers 192”

- Remco Universal strip builder USB 250

About Atlas Tank

Atlas Tank offers new-build aboveground storage tank construction and maintenance & repair services for existing structures. We are equipped with expert staff who utilize modernized programs, resources, shared services, and equipment to ensure projects are completed with an emphasis on safe work practices, quality, and schedule.

For each project we complete, we continuously seek the lowest costs, highest efficiency, and the safest practices so your project has the best opportunity to be successful. We use this strategy and motivation to deliver superior customer service and maintain strong business relationships with our customers.

Union Contractor

We are a union contractor who is signatory to the NTD Boilermakers Agreement for both new construction and tank repair.

Welcome to Emission Shield®

For the most environmentally friendly safe, and cost effective solution to reduce vapor loss , install Emission shield aluminum internal floating roofs in your above ground storage tanks.

-

ENVIRONMENTALLY FRIENDLY

75% reduction in vapor loss vs skin and pontoon roof designs.

-

CERTIFIED

Fully API 650 Annex H Code compliant.

-

SAFE

Significantly reduces fire danger.

Emission Shield® Features

The best solution for reducing product loss in storage tanks.

-

Innovative

Sets the standard for best available technology.

-

Express

25% less installation time.

-

Neatness

98% less weld length immersed in product.

-

Design

Streamlined design and efficiency of construction.

-

Cost Effective

40% fewer panels to erect and weld.

-

Efficiency

80% less rim butt welds.

How it works

We ensure quality & support for an innovative solution in the storage tank industry.

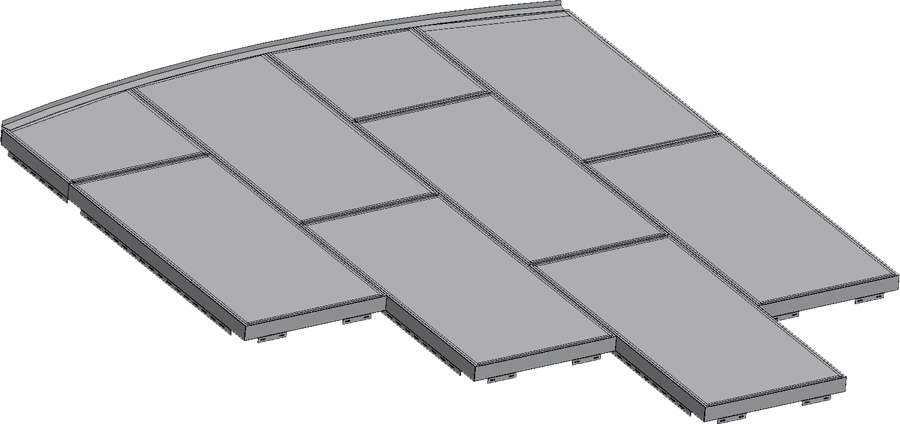

Emission Shield® is a full contact aluminum internal floating roof (IFR) system engineered to significantly reduce carbon footprint over traditional steel and aluminum internal floating roofs. Additionally, Emission Shield® virtually eliminates vapor space under the floating roof, significantly reducing fire danger. Emission Shield® sets the standard for best available technology (BAT) and is fully API 650 Annex H Code compliant.

Tank owners will appreciate Emission Shield's features and benefits over competing products because of the streamlined design and efficiency of construction. Installation time is reduced because there are 40% fewer panels to erect and weld on a typically sized roof. With 0% emission deck seams, vapor loss is reduced by 75% when compared to traditional skin and pontoon roofs. Emission Shield has 98% less weld length immersed in the product than competing products (4" vs. 20' per panel). This allows for more focused and rigorous NDE of the wetted (critical) area and vastly reduces the possibility of "hot panels" being created by product incursion.

The Emission Shield® floating roof incorporates the inherent buoyancy advantage of closed chamber floating roofs over raft style floating roofs while significantly reducing or eliminating the potential for product incursion into the closed compartments. Our design has approximately 80% less rim butt welds than competitors resulting in longer more stable rims. Emission Shield's low profile coupled with its cable suspension maximizes tank storage capacity.

See our Presentation

About TF Warren Transportation

We are under construction. This section is coming soon!

About Tarsco

Our Solutions

Tarsco has served industrial clients for over 40 years providing EPC turnkey solutions for above ground storage tanks and terminals. Tarsco specializes in engineering, construction, repair, maintenance services and are experts in API standards including 650, 620, and 653 as well as NFPA, AWWA, ASME Section VIII, and National Board Stamp “R” repairs. With global operations, Tarsco is well positioned to deliver unsurpassed service to our domestic and international clients.

Tarsco's professional management team offers a single source of contact to ensure their project is successful by being on schedule and on budget. Stringent Health, Safety, and Environmental policies are a major factor in the success of our projects. Tarsco's goal is to achieve zero incidents with no time away from the project, and this is accomplished by adhering to HS&E policies, in-depth training, and holding everyone accountable for safety. The result is a safer workplace for all as we strive to exceed our clients' expectations.

Why employ Tarsco?

- Welded storage tank systems with proven expertise in turnkey terminal and large scale projects

- Tank fabrication and construction

- Tank repair and maintenance

- Tank Insulation

- Full service contractor

- Service throughout the Western Hemisphere

- Privately held