About Brant Corrosion Control

Located in Brantford, Ontario, with easy access to major highway and border crossings, Brant Corrosion Control was established with the goal of becoming the premier lining and coating systems applicator in North America. With over 35 years of service, we continue to dedicate ourselves to the highest level of quality which people have come to know as Brant Corrosion Control.

Our Solutions

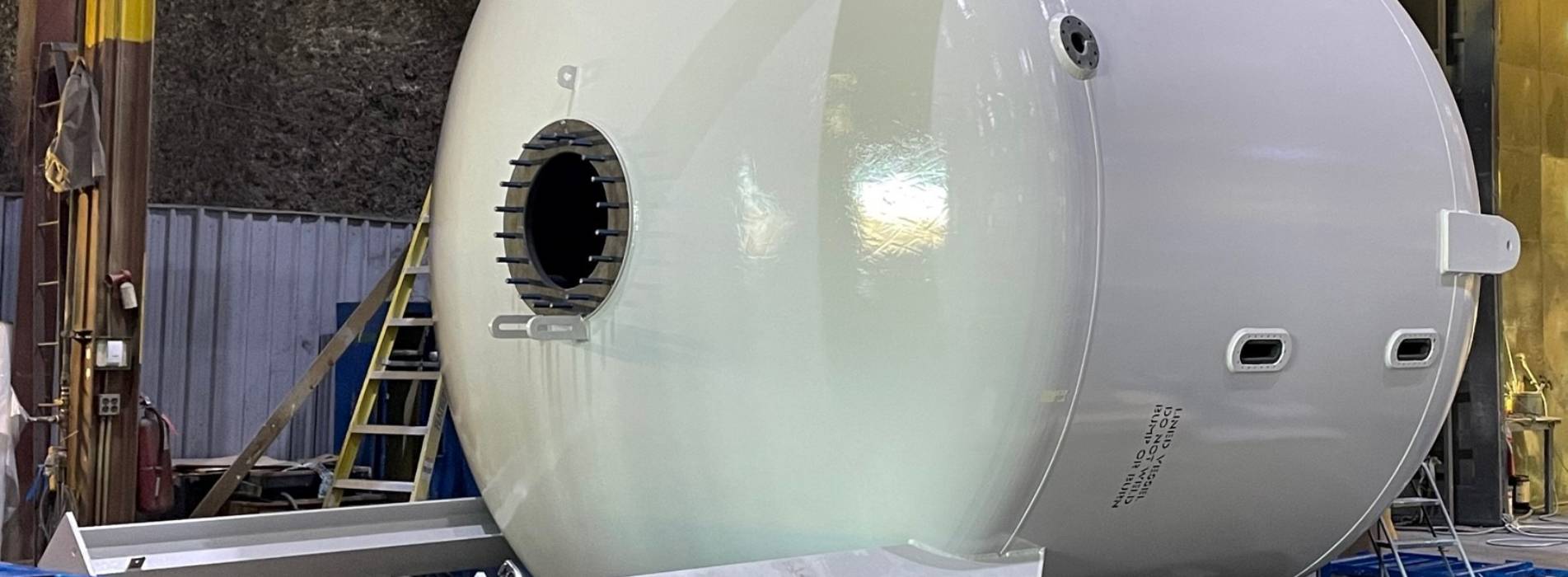

Our project management systems ensure all work performed by Brant Corrosion Control meets and exceeds your expectations. We accomplish this by being experts in the industrial application of protective coatings and linings for tanks, vessels, pipes, fans, agitators and other specialty fabrications.

Although Brant Corrosion Control's specialty services are used in many industries, we are particularly well known for our chemically resistant protective linings for the mining industry and water treatment tank industry.

Why employ Brant Corrosion Control?

- On-site rubber lining inspections and repairs

- Long history of successful projects

- Dedication to high quality

- Expert management and applicators

- Competitive pricing

- Contract maintenance service agreements

Industries Served

- Water & Wastewater

- Metals & Minerals

- Industrial Manufacturing

- Chemical Processing

- Food & Beverage

- Power Generation

- Steel Processing

Our History

Brant Corrosion Control was founded in 1984 by Ron Roswell as a two man operation with a 1,500 square foot facility. Today, as a Division of the TF Warren Group, we have over 70 team members and a 69,000 square foot facility.

Our tremendous growth over the past three decades shows a commitment to our goal of becoming the leading industrial applicator of protective coatings and linings in North America. Brant Corrosion Control is proud to be celebrating this milestone and would like to thank all of our team, customers and vendors for contributing to our success over the past 35 years.

Registered with